Capabilities

Multi-process casting and finishing—matched to your design, budget, and volume. One certified partner from design to delivery.

Overview

Glocon offers multiple ways to make metal parts—pressure die, investment, sand, and gravity casting, plus forging—so we match the process to your part, volume, and budget. We finish the build with machining and finishing (painting, anodizing, grinding, annealing, shot blasting) for assembly-ready parts. With ISO 9001 and IATF 16949 quality, a New Jersey support team, and optional warehousing and logistics, we take you from design to delivery

without the complexity.

Pressure Die Casting

Fast, repeatable parts with a clean, consistent look—ideal for mid- to high-volume programs where appearance and accuracy matter. We guide design choices so you get reliable quality at the right cost.

Alloys: Aluminum A380, A383, A360; Zinc Zamak 3/5

Capacity: Die-cast machines up to 1,000T

Part size: Up to 35 lb

Well-suited for housings, covers, and brackets

Gravity Die Casting

Pouring metal into a permanent mold under gravity produces strong, uniform parts with a smooth finish—ideal for dependable performance.

Alloys: Aluminum, Magnesium, Zinc — A356, A357, A380, 319, AZ91D, Zamak 3/5

Part size: Up to 90 lb

Smoother finish than sand casting

Stable dimensions for repeat orders

Investment Casting

When your part has fine details or complex shapes, investment casting captures them without heavy machining—great for stainless or carbon steel parts that must fit precisely.

Alloys: Stainless & Carbon Steels 304, 316, 17-4PH, 1045, 1020

Thin walls: Down to ~0.04 in

Part size: Up to 35 lb

Excellent surface quality and feature definition

Sand Casting

A flexible, budget-friendly choice for larger parts or shorter runs. Tooling is straightforward, and design changes are easier to accommodate.

Alloys: Carbon Steel, Aluminum & Cast Iron — A27, A216, A356, 319, A318, A48, A536

Part size: Up to 200 lb

Cost-effective for prototypes and low volumes

Great for bases, frames, and structural components

Value-Added Services

Quality details that improve

performance and appearance

Machining

We cut, drill, and shape parts for assembly-ready fit and finish.

- Tight features: bores, threads, flats

- Deburred and inspection-ready

- Quality documentation available

- Smooth hand-off to coating or delivery

Painting

Durable coatings in your color for protection and branding.

- Powder or liquid options to fit your spec

- Corrosion and wear protection

- Color, gloss, and texture matched

- Masking, plugging, and clear labeling

Anodizing

Long-lasting protective finish for aluminum with a clean appearance.

- Clear or color anodize options

- Consistent thickness for reliable fit

- Sealed for added corrosion resistance

- Cosmetic standards for visible surfaces

Grinding

Smooths surfaces and edges for a precise fit and finish.

- Flatness and parallelism brought into spec

- Deburrs sharp edges and radii

- Preps surfaces for coating or sealing

- Consistent surface texture (matte or fine)

Annealing

Controlled heat treatment to improve part stability and durability.

- Relieves internal stress to reduce distortion

- Improves machinability and

formability - Supports downstream finishing consistency

Shot Blasting

Cleans and textures parts to prepare them for coating or assembly.

- Removes scale, residue, and minor surface flaws

- Uniform matte finish for a consistent look

- Improves coating adhesion

- Set up for a wide range of part sizes and media

Case Studies

-

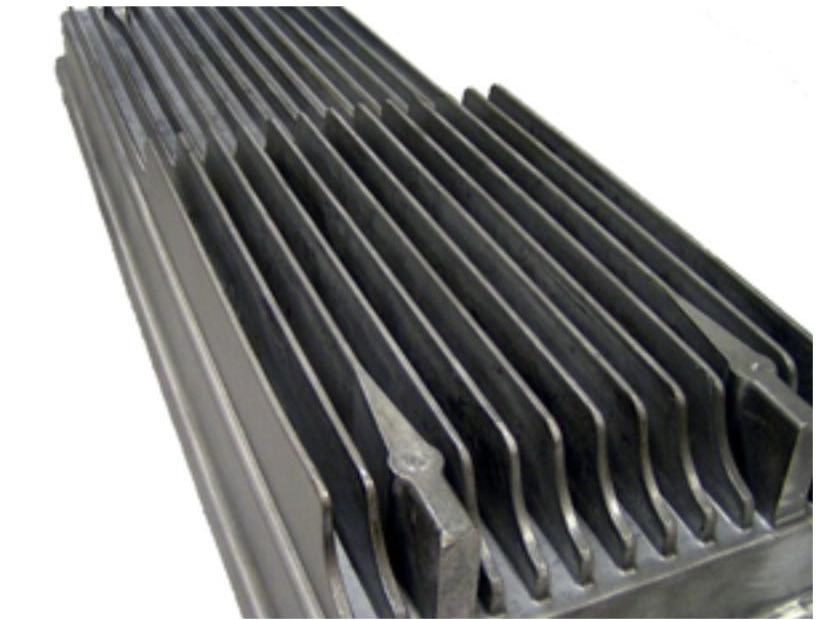

Precision Large-Format Heat Sink for Telecommunications

Glocon invested in advanced manufacturing capabilities specifically to meet this challenging requirement, implementing high-tonnage pressure die casting with precision process controls.

-

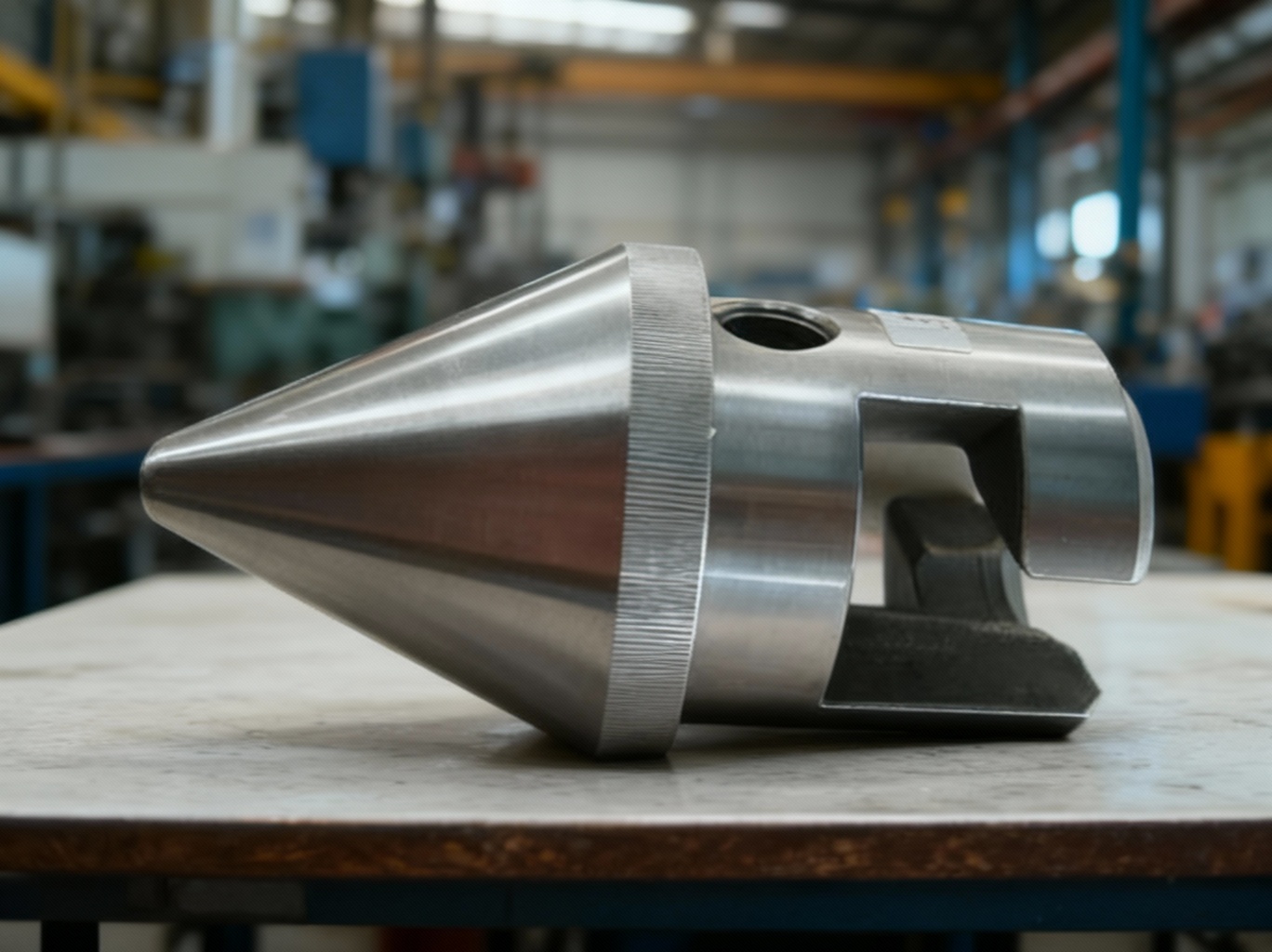

High-Performance Dust Filtration System for Heavy Equipment

Glocon completely reimagined the part design and manufacturing approach, transitioning from sand casting to precision pressure die casting.

-

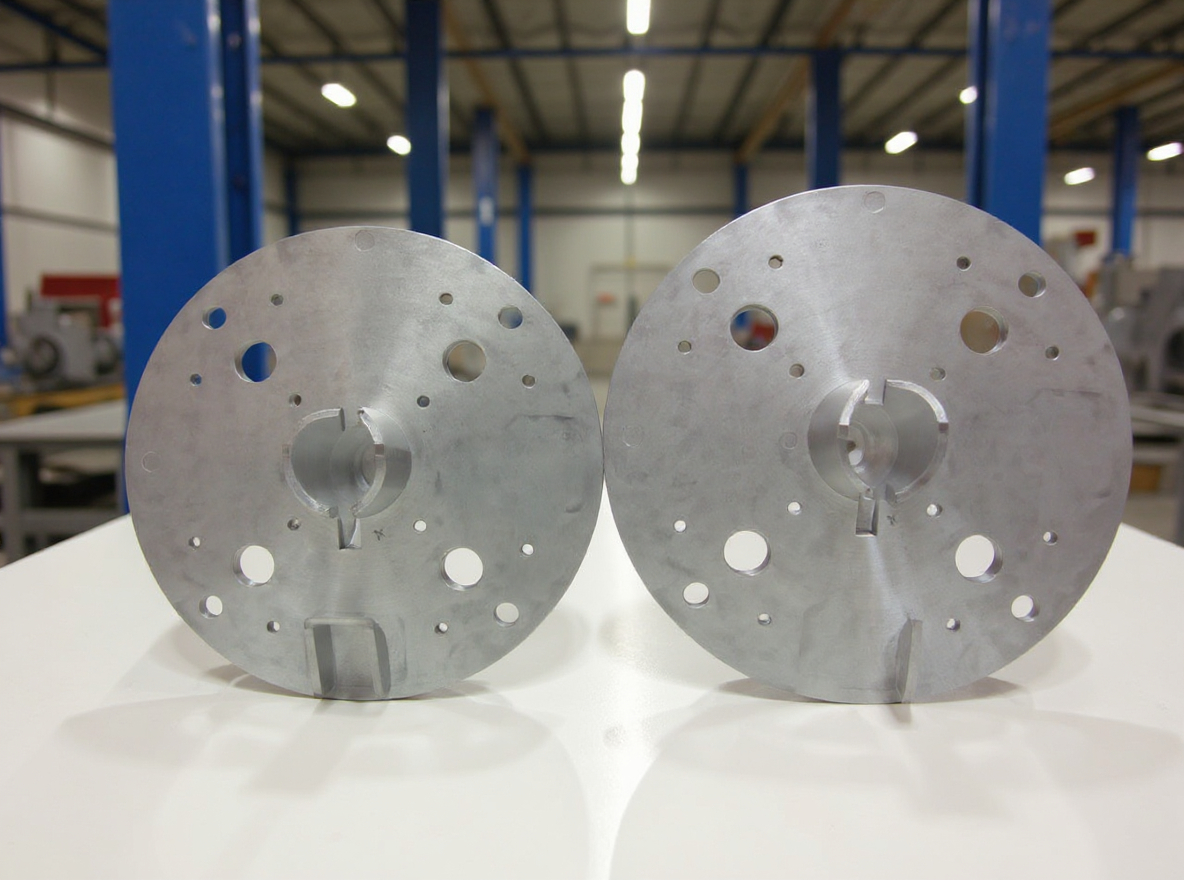

Composite Aluminum Fan Hub for Industrial Airflow

Glocon developed an innovative composite material approach, fusing aluminum with steel through gravity die casting to create a revolutionary fan hub design.